/Case%20studies%20(Pictures)/Mokveld/Mokveld%20-%20NL.jpeg?width=1080&name=Mokveld%20-%20NL.jpeg)

What is the most efficient way to heat a factory?

Ensuring proper heating in the workplace is essential to maintain employee comfort. Inefficient heating systems can result in uncomfortable working conditions. It is vital to use appropriate heating systems to create optimal conditions, particularly in factories. Continue reading for options and ways to do this in a sustainable way.

Issues to consider:

- Production hours

- Regulation(s)

- Heating demand

- Insulation (glass, windows, skylights)

- Tolerance of your production processes/products

- Cold air infiltration (depends on how often doors are opened in the building)

- Circularity (desired level of circularity for your building)

/Case%20studies%20(Pictures)/24%20Tailorsteel/247TailorSteel_Metal_Oxycom.jpg?width=775&name=247TailorSteel_Metal_Oxycom.jpg)

Residual heat

While searching for the right heating system, it is important to understand the concept of residual heat. Residual heat is “Unavoidable thermal energy that is generated as a by-product in industrial or commercial processes, and that would end up unused in air or water without a connection to a heat network.” Integrated with the right system, this residual heat can be used to heat up the building free of cost. Also, this residual heat can be used to warm up the supply air that is used to compensate for the negative pressure in the building.

“Waste heat is always CO2-free because it is a residual byproduct from the former production process”.

Prerequisites for installing a heating system

1. Heating demand around the year

It is important to look at if the factory needs heating. If the temperature only drops for a few hours or a weekend during winter, an electric heating system may be the optimum solution. Additionally, if there is a high internal heat load, heating is only necessary when the outdoor temperature drops significantly.

2. Processes and operations in a factory

If there are heat-intensive processes in a factory, there would not be a huge demand for heating because of the high internal heat load of the machines. In those cases, heat collects under the roof, and heat reuse can bring the hot air back to the floor using heat destratification fans.

3. Cooling vs. heating demand

According to IEA (International Energy Agency), cooling demand is growing at more than 3% a year for the next three decades, eight times faster than demand for heating in the last 30 years. If the cooling demand outweighs the heating demand, heat pumps can be an option for cooling in summer and heating in winter. However, it will have a negative impact on the power grid during high temperatures of peak summer.

It is important to balance the cooling and heating needs to achieve stable energy usage and efficient climate control in a factory. It is highly recommended to explore sustainable solutions for this purpose.

4. New building vs. old building

New buildings are highly insulated, and the heating demand is very low. Combined with the factory's production processes, the best possible efficient heating option can be chosen.

Generally, old buildings are not well-insulated. In case of higher temperatures in the building, the efficiency of heat pumps decreases, and hence it does not provide the desired result. Draft strips can be used to decrease heating demand and improve heating efficiency in older buildings. Furthermore, hybrid options (gas heaters/water boilers + heat pumps) can be an ideal heating solution for old buildings.

5. Negative pressure and heating

Negative pressure caused by exhaust systems in production machinery is a prevalent issue in many industrial places, particularly in production halls. During winter, people often experience uncomfortable cold drafts due to negative pressure. Heat Reclaim Modules can help to prevent this issue. The HR modules utilize the heat under the roof to warm up filtered outside air, which helps to compensate for the negative pressure. Additional heating capacity can be installed if the heat under the roof is insufficient to compensate for the negative pressure.

6. Moisture in the building

During winter, the production processes can result in moisture condensing on cold surfaces in the hall. In food industries, condensation against the ceiling is prohibited by food regulation agencies to avoid food contamination. Similarly, the use of cooling liquid in machining industries can elevate moisture levels in the hall and lead to condensation. To address this, it is necessary to increase the influx of fresh air into the building.

/Case%20studies%20(Pictures)/24%20Tailorsteel/Frank_Gelen-247TailorSteel.jpg?width=800&name=Frank_Gelen-247TailorSteel.jpg)

Four-season sustainable climate control for 247TailorSteel

Read how 247TailorSteel tackled negative pressure and achieved energy-efficient heating, cooling, and ventilation to create a fresh, healthy, and comfortable working environment.

/Case%20studies%20(Pictures)/Senoplast/Senoplast-Oxycom%20(1).jpg?width=775&name=Senoplast-Oxycom%20(1).jpg)

Energy-efficient heating

To heat a factory energy-efficiently, there are a few things to consider, such as insulation, a heating system, and a control system (along with all the factors mentioned above regarding the heating demand):

- Insulation: Ensure your factory is properly insulated to reduce heat loss. Poor insulation can lead to more energy use and higher costs.

- Heating system: Choose a heating system that is efficient and appropriate for your factory size and needs. Options include radiant heaters, forced-air heaters, and geothermal heating systems.

- Control system: Install a control system that can adjust the temperature and turn off heating in areas that are not in use. This will reduce energy waste and save money.

Read more in our blog: Step away from gas: 4-point plan for your factory.

Heating system

/Case%20studies%20(Pictures)/Senoplast/Senoplast.jpg?width=775&name=Senoplast.jpg)

1. Hybrid option

According to local regulations, gas heaters/water boilers in combination with heat pumps (Hybrid system) are a good solution for heating, especially for older buildings. New buildings, mostly, have heat pumps.

/Case%20studies%20(Pictures)/Mokveld/Mokveld%20tweetraps%20adiabatische%20koeling%20Oxycom%202.jpg?width=775&name=Mokveld%20tweetraps%20adiabatische%20koeling%20Oxycom%202.jpg)

2. Heat Pumps

Cooling liquid:

Although heat pumps are a popular choice for heating, they use cooling liquids/refrigerants that often contain HFCs, like R134a and R410a. It is advisable to steer clear of heat pumps that have high GWP (Global warming Potential) and ODP (Ozone depletion Potential) as they are dangerous to the environment and also go against the regulations outlined in the Montreal Protocol, which aims to phase out the use of HFCs by 2030.

If heat pumps are not installed properly, and there is any leakage, the HFCs might go into the building and be inhaled by the employees working in the building. This creates an unhealthy working environment for people and impacts productivity. Furthermore, the leaked HFCs into the atmosphere can have a hazardous impact on the environment. New cooling liquids like propane (R290) make heat pumps environmentally safe as they have low GWP. When it comes to the environment, natural refrigerants are the best choice due to their close-to-zero GWP and ODP.

/Case%20studies%20(Pictures)/M%20and%20G/M%26G.jpg?width=775&name=M%26G.jpg)

Insulation:

Effective low-temperature heating can only be achieved in well-insulated new buildings or older buildings with good insulation.

For more information on providing heating and ventilation sustainably (with the existing heating source) during winter, check out our blog: Sustainable heating and ventilation for your factory during winter.

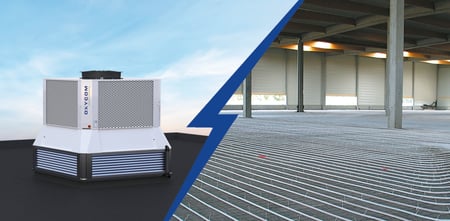

3. Floor heating

Floor heating is a widely used heating option in the world. It is comfortable, but it is slow, considering the reaction time to get the desired temperature. In addition, the energy cost of transporting the hot water through endless pipelines in the concrete floor is often not considered. On top of that, floor heating for a 1000 m2 hall of an industrial facility needs 5 km of plastic tubing. Furthermore, the issue of recovering plastic tubing from the concrete of demolished buildings is often not considered while using floor heating. Then, floor heating is not a circular option.

Read more in Floor Heating: An appealing option, or are there more complete alternatives?

/Case%20studies%20(Pictures)/Extra/What%20is%20evaporative%20cooling.jpg?width=775&name=What%20is%20evaporative%20cooling.jpg)

4. A 4-season energy-efficient solution: Heating, cooling, and ventilation in one!

The heating has many alternatives, such as gas heaters, floor heating, and radiators. Oxycom’s climate control is able to deliver heating, cooling, and ventilation in one. The patented IntrCooll climate control system can be combined with a natural ventilator box (no extraction fans needed) and a Heat Reclaim Module to create a healthy, fresh, and comfortable indoor climate all year round. Additional heating can be provided by connecting the Heat Reclaim Module with a heat pump. It is recommended to integrate existing heating systems with IntrCooll to achieve optimal energy efficiency in heating.

Read more: Step away from gas: 4-point plan for your factory

NEVER AN OFF-TRACK MOMENT in delivering comfort

Our system is highly flexible (per hour), easily adapting to temperature demands and seamlessly switching between cooling and heating modes. Transitioning from free cooling to heating and back again is effortless with our system. Compared to Floor Heating, Oxycom's climate control boasts an ideal EER and COP.

High energy savings around the year

Heating with Oxycom’s climate control can save up to 40% of energy consumption. However, that depends on the design and integration used for heating the factory. In the summertime, up to 90% of energy savings can be achieved with Oxycom’s sustainable cooling solution.

A sustainable alternative to floor heating

Aligned with SDG targets, Oxycom’s climate control is PARIS PROOF (meeting the stipulated targets of PARIS PROOF 2050).

It is an optimal design for heating and cooling with the ideal EER (Energy Efficiency Ratio) and COP (Coefficient of Performance).

/Book%20cover%20pictures%20(whitepapers%20and%20case%20studies)/EN/Challanges%20and%20opportunities/Challenges%20%26%20Opportunities%20mock%20up.png?width=800&name=Challenges%20%26%20Opportunities%20mock%20up.png)

Challenges & Opportunities for Energy-Efficient Climate Control

Discover how to create a sustainable and comfortable climate within your production facility. Download our whitepaper for free:

Related articles

See all articles/Case%20studies%20(Pictures)/Wildkamp/Wildkamp%20Raalte.jpg?width=450&name=Wildkamp%20Raalte.jpg)

One-season underfloor heating or four-season climate control while saving 14 tons of CO2 a year?

Wildkamp saves 14 tons of CO2 with a four-season climate control system at its new facility in Raalte. This blog explains why four-season climate control is an excellent replacement for underfloor heating.

/3D%20IntrCooll/IC-SF-HR-HPF.jpg?width=450&name=IC-SF-HR-HPF.jpg)

Sustainable heating and ventilation for your factory during winter

This blog explains how to sustainably provide a factory with a healthy and comfortable indoor climate during the winter.

Floor Heating: An appealing option or are there more complete alternatives?

Floor heating is an appealing approach to creating comfort on the shop floor but maybe not be the best option for the short and definitely not for the long term.

Back to overview:

Evaporative cooling