In recent years, much has been written about the importance of a healthy climate in the workplace, with fingers often pointing to the heat problems many production facilities face during the year's warmer periods. But also in winter, employees must work in a healthy and pleasant climate, i.e., a comfortable indoor temperature and sufficient ventilation. During winter, the latter often lacks on the work floor as all windows and vents are closed shut in favor of heat retention or draught prevention. Besides, the heating in production halls often seems to function far less efficiently and sustainably than is possible.

This blog explains how to sustainably provide a factory with a healthy and comfortable indoor climate during the winter.

Reusing used energy for heating

The outer shell of the building determines the required heating capacity for a production hall. When a building isn't sufficiently insulated, the building will retain a lot of heat in the summer and lose a lot of heat during the winter.

What people usually forget here is that heat accumulates under the roof due to thermal rise. Consequently, it can often be 5 to 10 ℃ warmer under the ceiling than on the shop floor. This heat is produced by factory processes, (old) lighting, the people on the floor, and regular heating (if present). One can reuse this collected heat to heat a hall by pushing it back to the shop floor via a ventilation system. By doing so, the hall's heating is (partly) realized with energy that has already been used and paid for. As a result, less or no energy at all is needed for the actual heating installation.

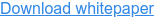

The Heat Reclaim module: heating and ventilation in one

The Heat Reclaim module, which fits the two-stage adiabatic cooling and ventilation system - the IntrCooll - is a smart solution for a pleasant indoor climate in winter. The Heat Reclaim module takes the warm air that collects under the ceiling and brings it back to the floor. Additionally, the Heat Reclaim can mix cold fresh outside air with the warmth collected under the roof to warm it up to a pleasant temperature and bring this to the shop floor.

This technique offers a solution for the following situations:

- When regular heating is necessary during the winter

When heating is necessary during the winter, the Heat Reclaim contributes to a more efficient and more sustainable way of heating. Because the Heat Reclaim minimizes heat loss by using the heat under the roof and blowing it back to the work floor, the necessary energy consumption for regular heating drops drastically.

- When there is a heat problem in winter

Some factories have a heat problem in the production halls during the winter too. Opening windows or ventilation hatches doesn't offer a solution at this time of year as it will cause a draught on the shop floor. When there is a heat problem in the production hall during winter, the Heat Reclaim module can ventilate the excess heat away by mixing the warm inside air with cold outside air to a pleasant temperature and bringing it back to the work floor.

Regardless of the situation, a significant advantage of the Heat Reclaim module is that it provides the factory with ventilation during the winter, and fresh outside air is continuously supplied for employees' benefit.

When there is no desired heating present, or the existing regular heating is no longer suitable, the Heat Reclaim module can be expanded with the Heat Coil. This double heating battery heats the air blown through the Heat Reclaim module and provides heating on the work floor.

When there is no desired heating present, or the existing regular heating is no longer suitable, the Heat Reclaim module can be expanded with the Heat Coil. This double heating battery heats the air blown through the Heat Reclaim module and provides heating on the work floor.

The Heat-Reclaim module in action: a few examples from the industry

More efficient heating and ventilation in an old production hall

The building complex where Canon Production Printing Netherlands prepares spare parts for service purposes was built in nineteen-eighties and is therefore poorly insulated and less than optimally ventilated. Last summer, 16 IntrCooll units were installed to provide employees with cooling and fresh air during the year's warmer periods. However, to provide the halls with enough heat in winter, the IntrCooll units would have to be switched off with the existing radiation panels running at full power. Therefore it was decided to fit half of the IntrCooll units with the Heat Reclaim module. With this addition, less electrical energy is needed for the radiation panels because the Heat Reclaim provides part of the heating. As a bonus, the halls are still supplied with fresh air during the winter.

Regulating the temperature for a bakery

In the German bakery Sinnack Backspezialitäten, the IntrCooll units provide space-, spot-, and process cooling for the production halls. Due to the enormous heat released in the production process, the bakery also needs to be "cooled" in winter, especially the halls where the baked products cool down. However, it is harmful to the baked goods when they come into direct contact with the cold winter air during cooling. As a solution, the IntrCooll units are partly equipped with the Heat Reclaim module. The module uses heat that collects under the ceiling to heat the cold outside air to a favorable temperature and blows it back into the production halls.

Refreshing the air in a metal machining factory

During the production process of BMI-Thegon, a metal machining facility, fumes are released, which must be extracted for the employees' well-being. For this purpose, an extraction system has been set up connected to the four existing IntrCooll installations. However, until recently, this meant that in winter, either all air was extracted when the IntrCooll installations were switched off, or an unpleasant draught developed when the IntrCooll installations were running. In both cases, this wasn't an ideal situation for the people on the floor. Last year, two of the four IntrCooll units were equipped with the Heat Reclaim module. The module uses heat released during metal machining to heat the cold fresh outside air with which the shopfloor is provided. In this way, the factory can now also be supplied with fresh air in the winter, without causing draughts.

How the Heat Reclaim module is used depends on the industrial sector. But in all cases, the Heat Reclaim is a suitable solution to regulate the temperature in a production hall during winter sustainably. The module also provides employees with fresh air. And when one invests in a smart climate system that provides optimal temperatures and ventilation in the other three seasons, it would be a shame not to be able to use it in winter too...

Download our whitepaper “Challenges and Opportunities for Energy-Efficient Climate Control”, and discover how you can create a comfortable and sustainable indoor climate within your production facility, all year round.

Download our whitepaper “Challenges and Opportunities for Energy-Efficient Climate Control”, and discover how you can create a comfortable and sustainable indoor climate within your production facility, all year round.

Want to know more about the Heat Reclaim module or the entire IntrCooll installation? Please contact us by filling in the form below or via +31 (0)572 349 400 or info@oxy-com.com.