Floor heating is an appealing approach to create comfort on the shop floor at first sight but maybe not the best option for the short and definitely not for the long term.

The Europe underfloor heating market is thriving on account of the numerous advantages associated with the adoption of underfloor heating, such as enhanced energy efficiency and comfort among others. Additionally, supportive European regulatory policies and standards for the adoption of energy-efficient systems, for the construction of green buildings are anticipated to drive the market growth for the underfloor heating, in spite of being a one-season solution only.

Rarely discussed floor heating issues

The energy cost of transporting the hot water through endless pipelines in the concrete floor is often not considered. In springtime, when hot and cold days follow up or alternate with each other, the solid concrete floor cannot adapt to the required temperature in the hall. The process is simply very slow due to the enormous amount of energy stored in the thick concrete floor. Somehow, in Northern Europe despite the disadvantages, architects and installers automatically advise floor heating for new buildings. It is not to blame any architect for this advice it was simply the best option available so far.

It should be mentioned that a comfortable and affordable healthy working environment includes cooling, heating, and ventilation all year round in all seasons and it should respond to the desired temperature requirements quickly and not after 12-24 hours, common with floor heating.

Cradle to Cradle: Issues to recover plastic tubing from concrete when a building is demolished

Awareness is rising, we see the first signs of resistance, from the advisors of the local communities, not allowing to install floor heating in industrial facilities due to the final lifecycle end of a building and the issues to recover the plastic tubing from the concrete.

When a building is at the end of its lifecycle, the concrete floor is broken down into larger pieces and transported from the site to a final recovery site where the concrete is broken down into very small pieces to be able to use the material again. In this process, the plastic tubes are broken down into small particles or even micro particles and these cannot be safely recovered from the concrete. They end up together with the broken concrete in driveways or as a stable underfloor for new highways and the microplastics mixed with the concrete eventually end up in nature.

Floor heating for a 1000 m2 hall of an industrial facility needs 5 km of plastic tubing, isn't that amazing?

The energy needed from the pumps to transport the hot water continuously through the 5 km of plastic tubing with a high internal resistance is extremely high.

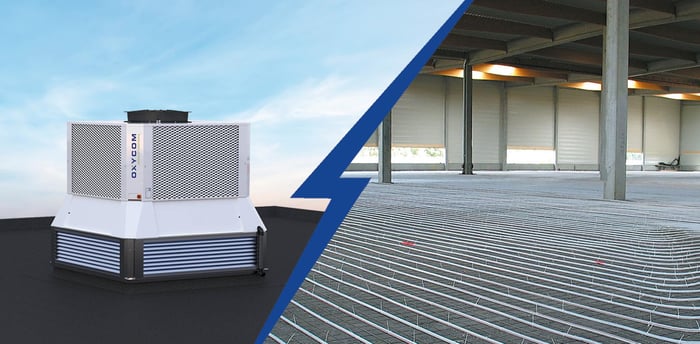

Alternative four-season IntrCooll technology

On average, only one IntrCooll Plus unit is required per 1000 m2.

From easy installation to lower energy requirements, IntrCooll stands as the best alternative compared to floor heating.

- Create a roof curb in the roof and lower the air inlet from the IntrCooll down into the building and basically, that's it!

- Connected to water and electricity supply and a comfortable and efficient four seasons ventilation, cooling, and heating system is in place.

- And no worries about hitting the underfloor heating system when placing a chemical anchor to connect heavy equipment to the floor anymore.

/Case%20studies%20(Pictures)/24%20Tailorsteel/Two-Stage%20adiabatic%20cooling%20metal%20industry%20247TailorSteel%20.jpg?width=690&name=Two-Stage%20adiabatic%20cooling%20metal%20industry%20247TailorSteel%20.jpg)

Oxycom's unique patented two-stage adiabatic cooling system allows for all required cooling, heating, and ventilation demands with up to 90% energy savings. It cools 4 to 7 °C deeper than direct adiabatic systems. The lower temperature means that approximately 30%-40% less air volume is required to achieve the desired indoor temperatures, and up to 70% less moisture is blown in compared to a direct evaporative system. This is extremely important for a comfortable indoor climate and prevents high humidity and annoying draughts/air displacement.

Our innovative climate control helps in achieving a healthy indoor environment and stay cool in the summer, warm in the winter, and ventilate with fresh, filtered air all year round. So, employees are always assured of a comfortable working environment at low energy and investment costs.

Read more about our innovative climate control:

Would you rather directly speak to an industrial indoor climate specialist to discuss your challenges? Please feel free to fill out the form below with your request. We are happy to help.