Water is one of nature’s most powerful refrigerants. Oxycom systems make maximum use of this unique property and evaporate water to generate cooling. We do this in several innovative ways. In this blog, we explain why water is an excellent alternative to the ozone-depleting R-22 refrigerant in conventional air conditioning and how water-based cooling works. Furthermore, we’ll show statistics on sustainability benefits and saved CO₂ emissions.

Why water?

Refrigerants function as the working fluids in air conditioners, heat pumps and refrigeration systems by absorbing and releasing heat as they undergo continuous phase transitions between the gaseous state and the liquid state in a closed refrigeration cycle.

R-22 (a hydrochlorofluorocarbon or HCFC) has long been the most widely used refrigerant in air conditioning systems but is nowadays increasingly being phased out because of its ozone-depleting behavior. Instead, chlorine-free replacements have gained popularity, most notably hydrofluorocarbons (HFCs), such as R-410A, R-407C and R-134a.

Water is also one of the many available refrigerants, having its own unique properties and refrigerant number (R718). Strictly speaking, evaporative cooling technology also uses water as a refrigerant, but instead of repeatedly being evaporated and condensed in a closed-cycle system, it is continuously being evaporated hereby cooling and humidifying a stream of air.

Water is highly suitable for this purpose, as it is one of nature's most powerful refrigerants, with an exceptionally high latent heat of vaporisation (2501 kJ/kg at 0 °C). As such, evaporating water at a rate of 1 L/h generates as much as 695 W of cooling power.

Conventional cooling technology

Vapour compression air conditioning is the most widely used technology for air conditioning, heat pump and refrigeration systems used for residential, commercial and industrial purposes. These systems consist of four main components through which the refrigerant is pumped in a closed cycle:

- The compressor adiabatically compresses the gaseous refrigerant, thereby increasing its pressure and temperature.

- The condenser coil allows the gaseous refrigerant to condense to the liquid state at constant pressure, thereby releasing heat to its surroundings.

- The expansion valve causes the liquid refrigerant to expand, thereby lowering its pressure and temperature.

- The evaporator coil allows the liquid refrigerant to evaporate to the gaseous state at constant pressure, thereby absorbing heat from its surroundings.

Evaporative cooling technology

In evaporative cooling, a stream of unsaturated air is brought into direct contact with a wet surface. The boundary layer around the wet surface is naturally saturated with water vapor. As unsaturated air flows along the boundary layer, water vapor will diffuse into the airstream, driven by a difference in vapor concentration. The water vapor content in the boundary layer is then restored to its natural saturated state by the adiabatic evaporation of water. The required latent heat for the phase change of water is taken from the sensible heat of the airstream, resulting in a lower air temperature.

The lowest possible temperature that can be achieved is the wet bulb temperature of the air, but is, in practice, somewhat higher due to limited efficiency. The saturation efficiency or wet bulb efficiency is defined as the ratio of the actually achieved temperature drop to the maximum possible temperature drop.

Download our whitepaper “Challenges and Opportunities for Energy-Efficient Climate Control” and discover how you can create a comfortable and sustainable indoor climate within your production facility.

Download our whitepaper “Challenges and Opportunities for Energy-Efficient Climate Control” and discover how you can create a comfortable and sustainable indoor climate within your production facility.

Generation of electricity

Before we look at the difference in energy efficiency between evaporative cooling versus conventional cooling, let’s take a look at what it costs to generate energy. There are various types of fuel available that power plants can use to generate electricity. For example, in the Middle East and lots of other parts in the world, they use oil and natural gas, thereby emitting vast amounts of CO₂. Power plants also require water for the generation of electricity, where it is mainly used for cooling. For instance, oil-driven power plants consume 3,19 liters of water and emit 0.84 kg of CO₂ per kWh of generated electricity.

Evaporative cooling versus conventional cooling

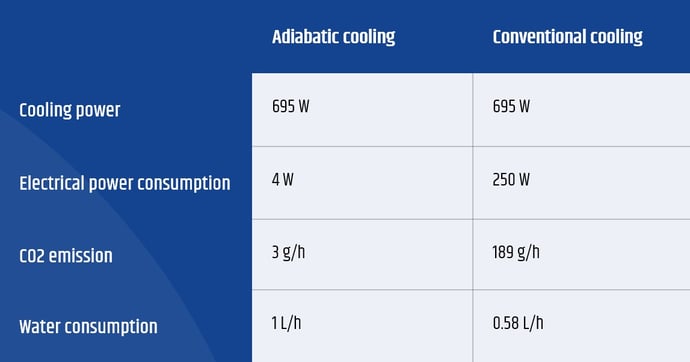

Comparative calculations have been performed for evaporative cooling and conventional air conditioning technology providing equal cooling power. Evaporative cooling with an arbitrary evaporation rate of 1 liter of water per hour has been chosen as the baseline, corresponding to 695 W of cooling power. Electricity is assumed to be generated in oil-driven power plants. Water intended to be used in evaporative coolers should preferably be of potable quality. Typically, desalination by means of reverse osmosis requires about 4 kWh of electrical energy per m³ of water.

For more information on the efficiency of evaporative cooling vs air conditioning, check our page: Evaporative cooling vs air conditioning.

Conclusion

Regarding the pure cooling aspect only, using evaporative cooling technology instead of conventional vapor compression air conditioning technology reduces electricity consumption and CO₂ emission by more than 90%.

Evaporative cooling technology inherently requires water to evaporate, but, existing vapor compression air conditioning systems indirectly consume significant amounts of water themselves. Therefore, increasing the adoption of evaporative cooling technology will have less impact on global water consumption than one may expect.

Find out how we use water as a refrigerant for our innovative IntrCooll: