Two-stage adiabatic cooling for the metal industry

Choose two-stage adiabatic cooling for a comfortable working climate, clean, filtered air and reduced chance of flash rust.

The top choice for your factory

The machine factory is at the core of your business. Productivity and output are essential. We know what you need.

Get comfortable

IntrCooll creates an optimal working climate. The pleasant temperature will increase comfort and productivity considerably.

Healthy and happy

Optimal ventilation is key for a healthy working environment in the metal industry. Our system cools with 100% fresh, filtered outside air.

Limit flash rust

Unique two-stage cooling enables our adiabatic system to cool deeper and secure a lower relative humidity. The chance of flash rust drops significantly.

Climate control for the metal industry

WIHO, an Austrian metalworking company, was looking for a sustainable way to cool their production halls. With the IntrCooll's comfortable cooling, they provide an optimal environment on the shop floor. Also, the reliability of the precision machines is guaranteed with a maximum temperature tolerance of 2°C. Check out the reference video on WIHO's experience with the IntrCooll.

/Book%20cover%20pictures%20(whitepapers%20and%20case%20studies)/EN/Whitepaper%20-%20Tips%20for%20the%20Metal%20Factory/whitepaper_Metal%20factory_EN.png?width=800&name=whitepaper_Metal%20factory_EN.png)

Tips & tricks for the metal industry

Discover valuable tips for creating an efficient working climate to solve the heat challenges in a metal factory. Download our whitepaper for free:

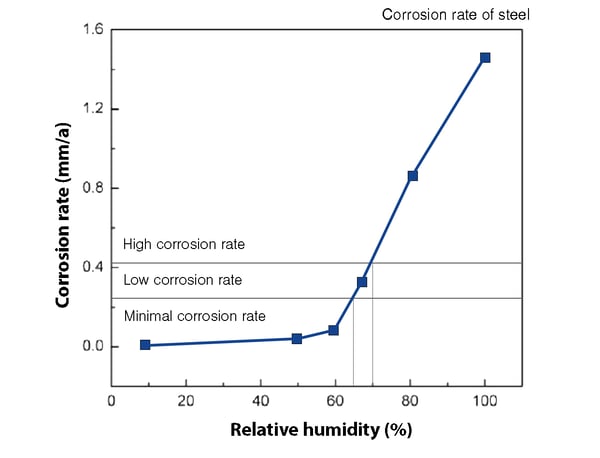

How to keep flash rust to a minimum

Rust and other oxidizing types of corrosion start when a surface is exposed to higher humidity for more than a day. The corrosion rate is defined in millimeters per year (mm/a); thus, the time a surface is exposed to higher humidity levels is essential. To prevent condensation or high surface humidity, a dew point lower than the surface's temperature must be maintained.

Oxycom's unique patented dual-stage adiabatic cooling system cools 4 to 7 °C deeper than direct adiabatic systems. The lower temperature means that approximately 30% less air volume is required to achieve the desired indoor temperatures, and up to 70% less moisture is supplied in to the building. This is extremely important to prevent flash rust in the metal industry.

IntrCooll's programmable thermostat is equipped with a relative humidity sensor that increases the room temperature setpoint when the relative humidity limit (adjustable) is reached. In this way, the space's relative humidity can be controlled.

![247TailorSteel [EN]](https://www.oxy-com.com/hs-fs/hubfs/Case%20studies%20(Pictures,%20PDFs,%20etc.)/Book%20cover%20pictures%20(whitepapers%20and%20case%20studies)/EN/247TailorSteel/247TailorSteel%20%5BEN%5D.png?width=800&name=247TailorSteel%20%5BEN%5D.png)

A comfortable and sustainable working climate with IntrCooll

247TailorSteel saw they had to improve their indoor climate to provide a healthy and productive work environment. With Oxycom’s sustainable cooling and ventilation system, IntrCooll, 247TailorSteel has created a stable and optimal working climate for its employees.

/Case%20studies%20(Pictures)/Neuman/Neuman%20Aluminium%20(15%20von%2019)%20copy.jpg?width=600&name=Neuman%20Aluminium%20(15%20von%2019)%20copy.jpg)

Unparalleled climate

Precision metalworking demands stable temperatures at all times. Our natural adiabatic cooling provides the metal industry with a sustainable and stable climate. IntrCooll saves up to 90% of energy.

/Case%20studies%20(Pictures)/24%20Tailorsteel/metal%20industry%20two-stage%20adiabatic%20cooling.jpg?width=800&name=metal%20industry%20two-stage%20adiabatic%20cooling.jpg)

We deliver excellent climate

Metal processing releases a lot of heat, oil vapors and welding fumes (dust and toxic gases). These conditions have a negative effect on the comfort and well-being of your employees. Therefore, cooling and optimal ventilation are fundamental. IntrCooll cools your factory with fresh, filtered outside air. The steady flow of ventilation refreshes the inside air completely, several times an hour. If required, the IntrCooll can be equipped with ionization.

Only the best for your employees

IntrCooll delivers air with a low temperature and good relative humidity. Fresh, cool air creates comfort and well-being for your valuable employees. The pleasant working climate results in increased productivity and higher output.

Unique two-stage cooling

IntrCooll uses two-stage indirect / direct adiabatic cooling. This natural cooling process cools fresh air in the first indirect step, using cold recirculation water, without water evaporation. The chilled air is cooled even further by direct evaporation with the patented Oxyvap® at this final step. Humidity levels remain low and chances of flash rust are minimized.

Year-round profit

Oxycom provides your factory with the perfect climate, even in winter and spring. IntrCooll's Heat Reclaim module reuses indoor heat to warm up fresh outdoor air.

IntrCooll is the perfect fit for all activities within the metal industry:

- Chipless machining - including cutting, punching, setting, rolling

- Machining - including turning, CNC milling, boring

- Fine machining operations - including sparks, grinding

- Thermal processing - including plasma cutting, laser cutting

- Surface treatment - including cleaning, gluing, coating

Climate control for the metal industry

IntrCooll

Our adiabatic cooling is the best natural and sustainable alternative to mechanical cooling. IntrCooll saves you up to 90% on energy consumption. You’re guaranteed a comfortable and healthy climate for your employees.

The solution for an optimal climate

What customers say about our show-stopping products.

/Case%20studies%20(Pictures)/24%20Tailorsteel/Carl_Berlo.jpg?width=450&name=Carl_Berlo.jpg)

A comfortable and sustainable working climate for 247TailorSteel

Carl Berlo, CEO, 247TailorSteel: "After Oxycom’s systems were installed, our employees are super happy with the indoor climate now". Read more to get the diverse perspectives from the management, operations, and production teams of 247TailorSteel:

Increased productivity and comfort at Pan Oston

Heico Booyink, Pan Oston: “We are very satisfied with Oxycom's energy-efficient solution which solved the heat problem in our coating department. Now we have a pleasant, constant temperature in summer and winter.”

/Case%20studies%20(Pictures)/MKW/MKW%20building.jpg?width=450&name=MKW%20building.jpg)

MKW® Group saves 55 tons of CO2 per year compared to a conventional solution.

Robert Wimmer, Production Manager - Press Technology, MKW® Group: “Two-stage adiabatic, with cooling of fresh outdoor air by up to 17°C, was one of the main reasons for choosing Oxycom's patented sustainable cooling solution.”

Let’s talk about your heat problem!

Let us help you create an optimal and sustainable working climate. Request a free consultation.

What we can do for you:

- Answer all your questions regarding indoor cooling and ventilation

- Analyze the challenges you are facing due to your current climate control

- Map out your current indoor climate situation

- Explain what the possibilities and benefits of adiabatic cooling are for your factory

- Provide you with tailored advice on an efficient and sustainable climate solution

Kor Foekens

Commercial Director

Request a free consultation.

We will get back to you shortly.