Evaporative cooling & humidity

Does evaporative cooling increase humidity?

Does evaporative cooling increase humidity? Depending on the type of evaporative cooling system that is used, indirect/direct evaporative or direct evaporative, the humidity in a building is less or more affected by a mildly higher humidity. How much the relative humidity within a space increases depends on the outside humidity level, the outside temperature, the desired temperature that is to be achieved, and the type of evaporative cooling system that is used.

Want to know more about evaporative cooling and humid climates click the link below:

Evaporative cooling and humid climates

Humidity and indirect/direct evaporative cooling

As mentioned above, the level of increase in humidity heavily depends on the type of evaporative cooling system that is used. For instance, Oxycom's patented indirect/direct evaporative cooling technology ensures up to 70% less increase in humidity than other direct evaporative cooling systems - ensuring a comfortable indoor climate for the occupants.

Healthy humidity

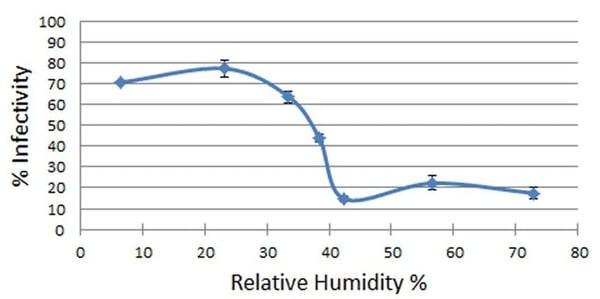

It is however also important to mention that bringing in some moisture into the air has its benefits. For example, a humidity level between 40 and 60% reduces the spread of dust and viruses within a production facility or building. Furthermore, it brings a level of comfort as the air that is too dry can irritate the eyes and throat. Thus it is essential to have a climate control system in place that provides the air with enough humidity for employees to feel comfortable as well as to protect them from the unlimited spread of viruses.

Degree of infectivity in relation to indoor humidity.

Humidity levels in a building

A prevalent misconception about evaporative cooling and humidity is that it would create a subtropical climate within a production facility or building. Two-stage evaporative cooling is capable of reaching lower temperatures and by the law of nature, lower temperatures hold lower amounts of humidity. In fact, due to the lower temperature, two-stage evaporative coolers need only 30 to 50% of the air volume needed to cool a building by direct evaporative coolers. Two-stage evaporative cooling systems used for cooling production facilities always ventilate the building with fresh, filtered outdoor air while removing the polluted indoor air. The fresh cooled air absorbs the heat whereby the absolute humidity of the inside air is reduced to comfortable levels. Thereafter it is extracted through an exhaust. This way, the moisture in the air doesn't get the chance to build up in the building or production facility, creating a pleasant climate for its occupants.

/Book%20cover%20pictures%20(whitepapers%20and%20case%20studies)/EN/MilliporeSigma/MilliporeSigma-EN.png?width=800&name=MilliporeSigma-EN.png)

Sustainable HVAC at MilliporeSigma Pharmaceuticals Distribution Center

MilliporeSigma, a leading supplier to the global life science industry, struggled to find an energy-efficient cooling solution in their distribution center at Visalia, California. With our patented two-stage adiabatic climate control, it could achieve a fresh, healthy, and comfortable indoor climate even during the worst heatwave of California.

Related articles

See all articles

Does evaporative cooling work in humid climates?

The more humid a climate is, the harder it is for a direct evaporative cooling system to cool effectively. This being said, indirect/direct evaporative cooling systems hold their performance far better in more humid regions, such as coastal areas, during the humid hours. How this works, you can read in this blog.

.jpg?width=450&name=Render%20-%20IC-NV-HR%20horizontaal%20+%20achtergrond-2-min%20(1).jpg)

This is how two-stage adiabatic cooling ensures optimal air humidity

Discover the many benefits of balanced air humidity and how to achieve this! Read this blog on indirect/direct adiabatic cooling.

Ventilation and humidity crucial against viruses, even after corona

Good ventilation, filtration and humidity are crucial against the airborne spreading of viruses in the workplace -- even after COVID-19. Learn more in this blog

Back to overview:

Evaporative cooling