People often ask what the resulting room humidity is when our adiabatic cooling is applied. This is only logical as one of the most significant concerns people have about adiabatic cooling is that it would create a subtropical climate with high humidity in the workplace. But the level of moisture released in the adiabatic cooling process depends entirely on the type of machine placed. Furthermore, there are health benefits associated with optimal humidity. How this works exactly, you can read in this blog.

Health benefits of humidity

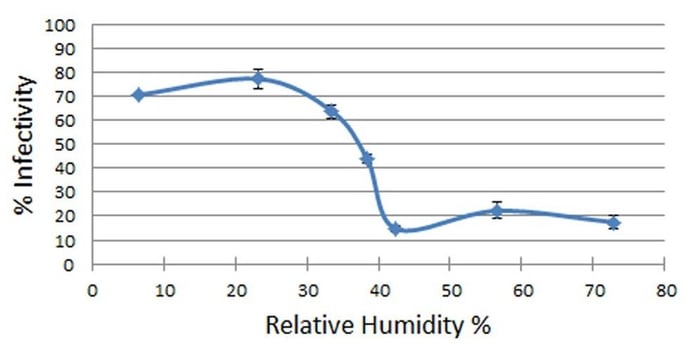

Traditional air conditioners dehumidify the air. Deep cooling causes the moisture in the air to condense on the cold heat exchanger. The cooled air then contains much less moisture. Comfortable in terms of temperature, but not always healthy. In dry air, our immune system isn't as able to defend itself against viruses, while the pathogens thrive better. Aerosols, tiny droplets that are potentially contaminated, travel a greater distance in dry air, increasing the possibility of virus transmission. In addition, dry air can also cause discomforts such as an itchy throat or irritated eyes. Therefore we recommend a relative humidity level of between 40 and 70%. This humidity level promotes protection against viruses and provides the necessary comfort for the throat, nose, and eyes.

To learn more about the health benefits of humidity, read our blog "Ventilation and humidity crucial against viruses, even after corona".

The advantages of two-stage adiabatic cooling

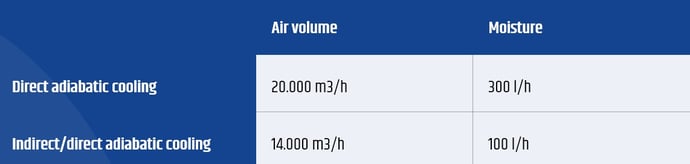

Direct adiabatic cooling is the type of evaporative cooling that is best known worldwide. During this process, water is evaporated directly into the air stream, significantly increasing the humidity of the air.

Oxycom developed a unique patented two-stage adiabatic cooling system, which uses indirect and direct evaporation. This technology cools 4 to 7°C deeper than direct adiabatic systems. The lower temperature means that approximately 30% less air volume is required to reach the desired indoor temperature, and up to 70% less moisture is blown in.

To illustrate, for the same cooling capacity in kW, direct adiabatic cooling brings 20 buckets of 10 liters of water more per hour into the room to be conditioned than indirect/direct adiabatic cooling!

* The indirect/direct adiabatic cooling requires about 30% less air volume to achieve the same cooling capacity.

* The indirect/direct adiabatic cooling requires about 30% less air volume to achieve the same cooling capacity.

* Numbers are per unit.

An indirect/direct adiabatic system can hold the desired indoor temperature and corresponding humidity much longer than a direct adiabatic system that does not cool deeply enough at higher humidity and brings in 70% more moisture, which does not improve comfort.

When working with materials such as paper or plastics, excessive humidity has a negative impact on processability. In contrast to direct adiabatic cooling systems, an indirect/direct adiabatic cooling system ensures that humidity levels remain lower, preventing condensation on cooled materials.

All in all, indirect/direct adiabatic cooling offers optimal air humidity where comfort and health are paramount. Because this technique can cool deeper and therefore adds less moisture to the air, two-stage adiabatic cooling suits all industries.

Want to know more about what our two-stage adiabatic cooling can do for you? Please contact us at +31 572 349 400, or fill out the form with your question: