/Case%20studies%20(Pictures)/M%20and%20G/Sustainable%20cooling%20and%20heating%20M%26G.jpg?width=1080&name=Sustainable%20cooling%20and%20heating%20M%26G.jpg)

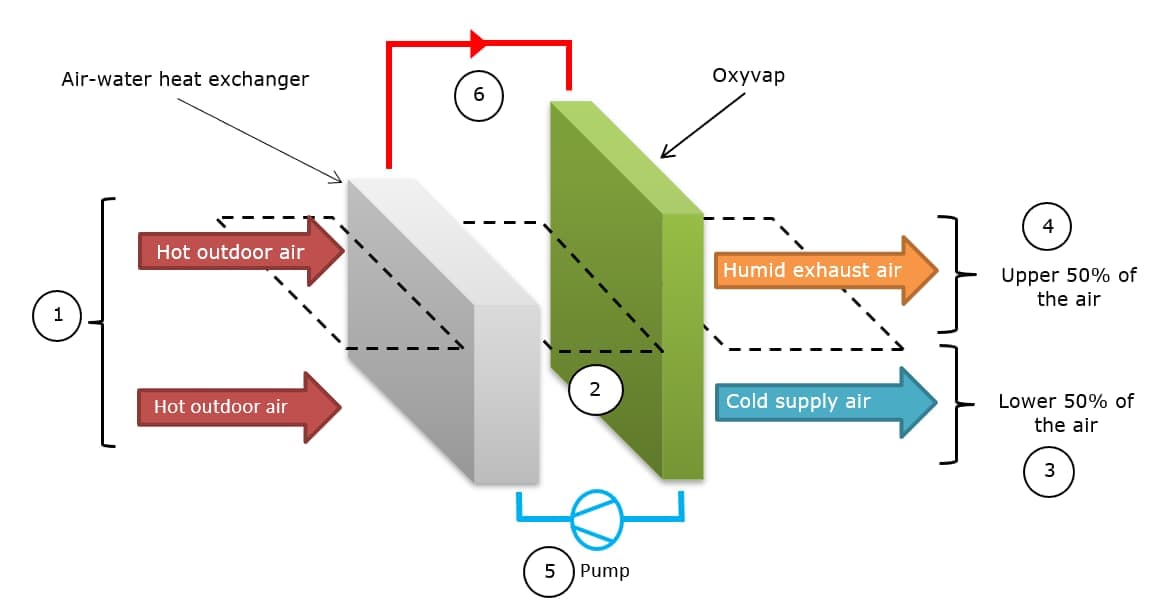

Two-stage evaporative cooling

Cooling up to 7 ℃ deeper with up to 70% less moisture

There are several ways to apply the evaporative cooling process:

- direct evaporative cooling

- indirect evaporative cooling

- indirect/direct evaporative cooling

Indirect/direct cooling, also known as two-stage evaporative cooling, uses both indirect and direct cooling techniques to cool the air.

The first indirect "cooling step" uses cold recirculation water to pre-cool the ambient air in a heat exchanger. Because no moisture is added, the air reaches a lower dry bulb and wet bulb temperature than the outside air when leaving the heat exchanger.

The second direct adiabatic "cooling step" cools the air further through the wet evaporative media. As a result of this two-step cooling process, the air can be brought down to a much lower temperature and is therefore not capable of containing high amounts of humidity.

Oxycom's IntrCooll makes use of two-stage evaporative cooling. This two-stage evaporative cooling system has many benefits as opposed to the single-step evaporative cooling systems.

Benefits of Oxycom's two-stage evaporative cooling system

- Environmentally friendly alternative, with 90% lower energy consumption

- Cools up to 7 ℃ deeper than single-step systems

- Brings up to 70% less moisture in the supplied air than direct systems

- Up to 30% less water consumption than single-step systems

Why two-stage adiabatic cooling is different from direct adiabatic cooling

Challenges & Opportunities for Energy-Efficient Climate Control

Discover how to create a sustainable and comfortable climate within your production facility. Download our whitepaper for free:

Related articles

See all articles

Evaporative cooling vs air conditioning

This page provides a clear comparison between evaporative cooling and air conditioning - find out what advantages work best for you.

/Case%20studies%20(Pictures)/MilliporeSigma/Two%20Stage%20evaporative%20cooling%20USA.jpg?width=450&name=Two%20Stage%20evaporative%20cooling%20USA.jpg)

What types of indoor cooling (AC) options are there for production facilities?

This blog illustrates various indoor cooling options to ensure a healthy and productive climate in your production facility - with stable indoor temperatures, air humidity, and optimal air quality.

/Case%20studies%20(Pictures)/24%20Tailorsteel/metal%20industry%20two-stage%20adiabatic%20cooling.jpg?width=450&name=metal%20industry%20two-stage%20adiabatic%20cooling.jpg)

5 tips to improve the indoor climate of your production facility

This blog provides five tips to improve the indoor climate of your production facility to keep your employees happy, healthy, and productive.

Back to overview:

Evaporative cooling