Austria

KIEFEL Packaging GmbH

Sustainable hall cooling in the plastics industry saves 87% CO2 and 78% operating costs

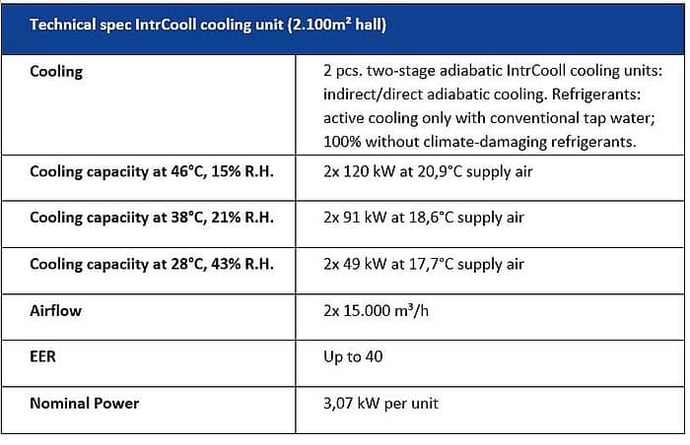

In the reference project Kiefel Packaging in Micheldorf, Austria, INFRANORM Technologie shows, how a 2100m² production hall was cooled with 87% energy saving compared to conventional compression refrigeration systems and without any climate-damaging refrigerants. Only with the power of the natural refrigerant water and the innovative Oxycom's two-stage adiabatic cooling technology. As a result, 78% of the operating costs have been saved compared to conventional solutions.

Description and technical details

Micheldorf-based Kiefel Packaging GmbH, technology expert for packaging solutions, is one of the world's market leaders in the design and manufacture of machines and tools for processing plastics.

As part of the construction of a new building, Kiefel decided to equip the 2.100 m² production hall with the most energy-efficient cooling technology available. At the same time, the aim was to achieve optimum hall air quality and a pleasant room climate for the employees by introducing as much fresh air as possible.

Mr Dietmar Huemer, Facility Manager at Kiefel Packaging, relied on the innovative solution IntrCooll from Oxycom. A solution that is especially developed for production facilities and enables a particularly sustainable and energy-saving cooling of the production halls.

Benefits for industry and the environment

The new Oxycom's IntrCooll system, for the cooling of production halls, does not use any climate-damaging refrigerants. "Compared to conventional air conditioning, it reduces Kiefel's energy requirements and CO2 emissions by 87% and simultaneously lowers operating costs by 78%," says Christian Lindner, CEO of INFRANORM® Technologie GmbH. "According to the Dutch Green Building Council DGBC, hall cooling with Oxycom's IntrCooll is already PARIS PROOF. This means that IntrCooll meets the criteria of the UN Climate Protection Convention of Paris for the year 2050".

In terms of temperature reduction, Oxycom's IntrCooll can easily compete with conventional air conditioning systems. Even at extreme outside temperatures of 37 °C, the supply air temperature is a pleasantly cool 19 °C. The cooled fresh air is introduced through two grey textile air ducts. These ducts were adapted to the hall and to the customer's requirements by means of individual laser perforations, to ensure an even and draught-free air distribution.

Operating modes

Two-stage indirect/direct adiabatic cooling

The innovative two-stage cooling mode is automatically activated when outside temperatures rises. In the first indirect adiabatic cooling stage, cold circuit water is used to pre-cool the ambient air without humidifying the air. In the second stage, direct adiabatic cooling is used to further cool the air using the patented "Oxyvap®" from Oxycom. The cooling capacity and comfort are further increased because the "poor" moist air is discharged to the outside due to the special fin structure and only the drier, cooler part is used for the supply air.

The combined wet bulb efficiency rises to 114% and enables outstanding cooling performance, such as cooling the 37 °C hot outside temperature to 19 °C with 15.000 m³/h supply air at a power consumption of approx. 3 kWh.

With a VDI 6022 certificate and fully integrated silver ions in the Oxyvap®, as well as hygiene-optimised water management, the hygiene of the air introduced is permanently ensured.

Free cooling mode

The second operating mode is the free cooling mode. Here, low outside air temperatures (e.g. <16 °C) are used to cool the building. While conventional air conditioning systems recirculate the hall air to cool the building, IntrCooll introduces free, cool and fresh outside air into the hall.

Differences compared to single stage direct adiabatic cooling systems

Compared to single-stage direct evaporative cooling, a considerable increase in performance is achieved, since 5-7 °C lower supply temperatures are achieved. Comfort is also improved, as up to 50-60% less humidity is introduced into the room, resulting in a comfortable indoor climate that remains within the ASHRAE standard.

Kiefel's project awarded for the Energy Globe Award

The project for hall cooling at KIEFEL Packaging has won the Energy Globe Award, Upper Austria, as a game changer in room cooling for economically and ecologically sustainable hall cooling.

IntrCooll

IntrCooll is the desired solution to cool large halls and especially production halls in an energy-saving, economical and sustainable way. As a result, people and machines are protected against overheating, an optimal hall climate is created and productivity and employer attractiveness are strengthened.

Advantages of the reference installation:

- 87% energy savings

- 87% CO2 emissions reduction

- 78% operating costs reduction

- Create a comfortable indoor air climate

- Natural refrigerant water

- Safe hygiene through VDI 6022 certificate

- 100% absence of climate-damaging refrigerants

- Achieves temperatures comparable to those of a conventional air conditioning system

- 100% fresh air

"Thanks to the installation of Oxycom's IntrCooll, INFRANORM® has already significantly reduced temperatures in our production in the summer of 2019 and created a draught-free supply of fresh air for our employees. The installation is a great gain in terms of workplace quality at our production facility and is also very energy efficient and sustainable."

Managing Director, CEO Robin Roth, Kiefel Packaging

Return to overview:

ReferencesLet’s talk about your heat problem!

Get in touch with Oxycom and see what our adiabatic cooling can do for your factory.

Kor Foekens

Commercial Director

How can we help you?