Generally speaking, three types of cooling are used in production facilities:

- Process cooling with which machines/production lines are pre-cooled to increase process efficiency

- Comfort cooling with which the entire, or large areas are cooled and ventilated

- Spot cooling with which only certain areas where people are present are cooled and ventilated.

In this blog, we further discuss what spot cooling entails, the benefits of spot cooling, and in what situations it can best be applied.

Spot cooling: how does it work?

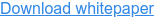

Spot cooling creates cool zones in those areas where cooling is required. This can be achieved in several ways. In all cases, an air hose is placed above the designated cool zone. When a textile air hose is used, the chilled air is slowly released through the micro-perforation of the fabric and ‘falls’ onto the people present in the cool zone. If a more concentrated spot cooling is necessary, nozzles can be fitted into an air hose to direct the airflow directly onto those present. Depending on the level of cooling required, the velocity at which the air is blown in can be increased. To prevent a draught, the higher the speed of the airstream, the higher the temperature of the air needs to be. This has to do with the chill factor of the airflow. For example, at an air temperature of 30 ℃, if the air flows in at 2 m/s, the air will feel 4 ℃ colder. At high temperatures and high humidity, the comfort zone stays in tact when the airspeed increases (see psychrometric chart below). The blueline represents the comfort zone.

In what case is spot cooling most suitable?

There are several situations where spot cooling can provide an affordable alternative to over-all comfort cooling. Production facilities that work with a lot of heat, such as glass factories, will generally not have a climate control system in place. Mainly because it is almost impossible to cool against the heat radiation, and even so, it would simply be too costly. In such a situation, spot cooling is an affordable solution to provide relief for people working in the vicinity of the source of radiation such as a melting oven.

In the case of a large production hall, such as in a bakery, where people are working close to a bakery oven with high temperature and radiation, and the rest of the hall is unpopulated, spot cooling provides a very suitable solution to create a comfortable climate only there where people are present. Cooling the entire hall would be a waste of energy.

In addition, when there is a loading area within a factory and the outside doors constantly open and close, it can be challenging to provide a pleasant temperature with all-round comfort cooling in that area. This especially the case in the summer, during which hot outside air flows in, and the cooler situated in the lower levels, escapes through the doorway. In this case, spot cooling can be a great solution to provide the stations were people are working in those areas with a comfortable climate.

To summarize, spot cooling is especially suitable for production facilities where only specific areas can or need to be cooled and ventilated to increase the comfort of employees. In this situation, spot cooling provides a more sustainable and affordable solution than all-round comfort cooling as it uses less energy.

Download our whitepaper “Challenges and Opportunities for Energy-Efficient Climate Control”, and discover how you can create a comfortable and sustainable indoor climate within your production facility.

Download our whitepaper “Challenges and Opportunities for Energy-Efficient Climate Control”, and discover how you can create a comfortable and sustainable indoor climate within your production facility.

Calculating and designing spot cooling

The calculation required for spot cooling is somewhat different from the calculation that is made for all-round comfort cooling. In the case of spot cooling, one needs to look at how the air should be distributed, at what temperature, and at what velocity to provide the required cooling effect. For example, as described above, the actual air temperature can differ very much from the ‘perceived temperature’ or ‘apparent temperature’, depending on the velocity at which the air flows in. Designing spot cooling, therefor, is specialized work. At Oxycom, we have the knowledge and the know-how to calculate the exact spot cooling you need to create the optimal cool zone(s) within your factory.

Spot cooling and two-stage evaporative cooling

Spot cooling is especially suitable in combination with Oxycom’s two-stage evaporative cooling technology. The advantage of the two-stage evaporative cooling system, IntrCooll, is that it allows you to use air with a substantially lower temperature than direct evaporative systems. This makes it ideal for spot cooling, especially in combination with Oxycom’s unique AirOptimizer.

In comparison, applying spot cooling in combination with mechanical cooling costs a lot of energy to cool and ventilate the amount of air that is needed, and the low temperature with which the air is blown in will result in an uncomfortable draught.

In conclusion, if your production hall needs cooling only in those specific areas where people are present, then spot cooling offers a sustainable and affordable solution.

Want to know more about what Oxycom can do for you to create a comfortable and sustainable working climate within your production facility? Feel free to contact us and talk to one of our experienced evaporative cooling specialists: