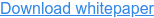

It is commonly known that people perform better in a cool and healthy environment. Therefore production facilities must provide a comfortable indoor climate for employees. With temperatures on the rise worldwide, it has become a necessity to implement a form of climate control to create such a working environment. One of the considerations that need to be made when choosing a climate control solution for a production facility is the heat load of the building. The heat load is a calculated thermal quantity used to establish the required cooling capacity to maintain a comfortable indoor temperature. This calculation considers all potential heat sources, including solar radiation, people, machines, lighting, and so on within the building. In other words, the total heat load of a building or space comprises of the external and in the internal heat load.

In this blog, we will further discuss the external and internal heat load of a building, and in what ways these can be reduced with some straightforward adjustments.

External and internal heat load

The external heat load of a building is made up of:

- the solar heat

- on and through the glass of windows and skylights

- on outer walls and roofs

- the outside air temperature

- infiltration of outside air (when a building is ‘leaky’, and air can flow into the building)

- Ventilated air - in the case of hot outside air that is blown in without being cooled down to the desired temperature.

The internal heat load of a building consists of:

- the heat emitted by the people present. The amount of heat depends on the number of people and the level of their activity

- the electrical lighting (some electrical lighting may give off more heat than others)

- the heat emitted by machinery, equipment, and the production process (ovens, generators, machine milling (process), etc.)

- transmission heat from surrounding areas (such as the heat exchange between unconditioned and conditioned spaces)

Reducing the heat load with straightforward adjustments

The architectural design of a building has a significant influence on the external heat load. For instance, smart choices can be made in the placement of windows in relation to the sun, to lessen the impact of the sun’s radiation. However, once a production facility has already been built, there are minimal structural adjustments that can be made to reduce the external heat load of the building. Yet, some straightforward changes can be made to reduce the external heat load.

Consider fixing any leakage in the exterior walls of the building. Single glazed windows can be changed to solar control (double glazed) windows and/or a sun reflective coating or foil can be applied to the glazing. The coating allows the sunlight to pass through the glass while reflecting away a significant degree of the sun’s radiation. Other options include installing sunblinds, coating the glass panes with sun reflective chalk or paint, or covering the windows with a sun reflective fabric.

Reduce the external heat load even further by painting the roof white of a lighter shade of grey to reflect the sun’s radiation. A similar effect can be achieved by placing solar panels on the roof.

The internal heat load can be reduced by changing regular lighting for LED-lighting instead. LED-lights produce minimal heat, and as a bonus, use considerably less energy than regular lighting.

Extractor hoods placed above heat-producing production processes can extract a great deal of the heat that is generated in the process.

If feasible, consider placing a screen around heat-generating equipment to reduce the amount of heat they radiate into the production facility. Some heat-generating machinery, such as internal cooling machines could even be placed outside of the production hall to eliminate their influence on the internal heat load.

By implementing the adjustments listed above the heat load of a production facility can be reduced considerably. As a result, the required cooling capacity of a climate control solution will also decrease. Consequently, less energy will be needed to provide a healthy and comfortable working environment.

Download our whitepaper “Challenges and Opportunities for Energy-Efficient Climate Control” for more information on how to create a comfortable and sustainable indoor climate within your production facility.

Download our whitepaper “Challenges and Opportunities for Energy-Efficient Climate Control” for more information on how to create a comfortable and sustainable indoor climate within your production facility.