The cold chain is essential in ensuring the safety, organoleptic quality, nutritional content and market value of perishable foodstuffs from harvest to consumer. Worldwide it is estimated that 15% of the electricity consumed is used for refrigeration. Despite this considerable operating cost, some refrigeration systems are suspected of losing up to 20% of their charge each year, resulting in increased energy consumption, emissions and service costs. New and alternative refrigeration technologies with environmentally friendly refrigerants are necessary to minimize the use of ozone-depleting cooling refrigerants. Energy consumption-reducing technologies such as PreCooll can lower the energy demand dramatically.

Evaporative upgrade of condenser units: how does it work?

High outside temperatures make condenser units lose efficiency and reliability. Evaporative pre-cooling is a relief for your chiller. It will drastically improve its efficiency, even in extreme heat. The working principle of Oxycom's PreCooll is based on a natural cooling technique which realizes evaporative pre-cooling of air through the evaporation of water. No harmful HFC gassess are required.

The core of the innovative PreCooll system is the HydroChill fin technology, the evaporative media, is embedded in the Oxyvap®. It is known for its extremely high efficiency and low pressure drop. PreCooll creates a cool microclimate around your industrial condenser unit. Adiabatic cooling of the ambient air before it enters the system is the fastest way to lower energy consumption. Ensuring a steady supply of cold air to the condenser coil, not only boosts efficiency but reduces peak power, unburdens overloaded electricity grids. It also contributes to longer equipment lifetime and lower maintenance costs.

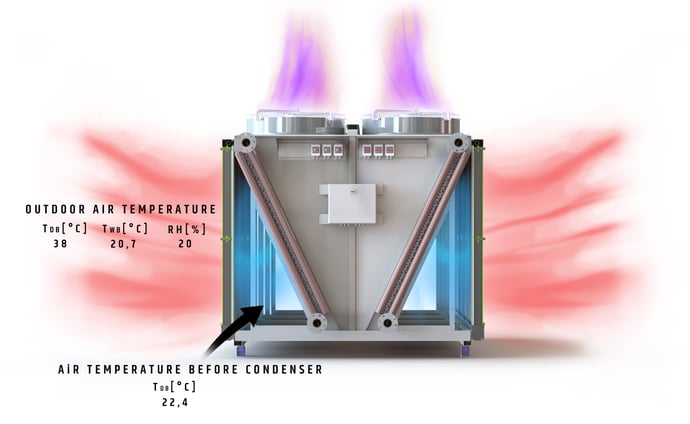

This picture shows that, in the presence of a PreCooll system, the condenser inlet air temperature

drops to 22,4 °C when outside air conditions are Tdb=38 °C and RH=20% (according to Australian standards).

"Oxycom’s PreCooll does not require any harmful HFC gasses"

Water management system

We know that it takes 1 m3 of water and large amounts of fossil fuel to produce 250 kWh of electricity, while evaporating 1 m3 of water delivers a stunning 695 kWh of cooling power. To achieve maximum efficiency and minimal water usage, PreCooll can be equipped with a pumping station which includes the circulation pump, water treatment module, and control system with sophisticated algorithms that monitor the ambient conditions and determine the optimum operation modes. This ensures that the PreCooll system is active only when necessary. The fully automated water management system, AquaMizer®, continuously monitors water quality, drains the system and refreshes the water when mineral levels reach certain values.

Retrofit existing and new condensers installations

Oxycom’s PreCooll system can be used to retrofit condensers installations. The Oxyvap® is known for its extreme low pressure drop; therefore, it does not affect the airflow through the condenser coils. Gas coolers, using CO2 as the refrigerant, benefit especially well from this principle. Not only is the energy consumption reduced considerably by the use of a PreCooll unit, but transcritical cooling processes will also be transformed into subcritical ones. Besides saving energy, the avoidance of transcritical cooling extends the lifetime of the cooling system considerably.

Fitting a cooling installation with PreCooll reduces energy demand. Oxycom’s PreCooll system is simple and effective. By lowering the inlet air temperature by as much as 25 °C (45 °F) in warm climates, the PreCooll system will result in significantly reduced operating costs, regardless of the type of refrigerant. Furthermore, Oxycom PreCooll systems realize up to 40% cut back in the environmental footprint in terms of reduced CO2 emission and HFC gasses.

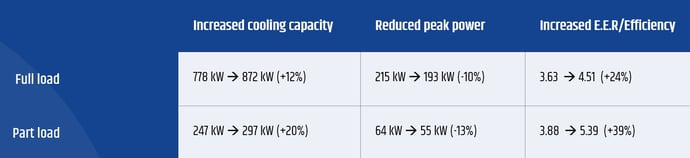

Laboratory test results confirmed by one of the world’s leading HVAC manufactures measured the following benefits in the presence of Oxycom’s PreCooll:

- Increase in EER: 1.90% per °C pre-cooling

- Increase in cooling capacity: 0.99% per °C pre-cooling

- Decrease in power consumption: 0.90% per °C pre-cooling

What about maintenance?

Our Oxyvap® pads are self-cleaning and made of inorganic materials with the lowest possible air resistance, guaranteeing safe operations and maximum savings for many years.

Conclusions

Sustainable refrigeration systems are essential for the world to meet the demands of a growing population whilst addressing climate change. Oxycom’s PreCooll represents a profitable investment in that it helps save up to a third on the operational cooling costs with a relatively small investment. PreCooll is an environmentally friendly solution that increases the cooling capacity of new and existing cooling systems and, at the same time, ensures:

- up to 40% energy savings per year

- up to 30% peak load reduction

- up to 40% lower CO2 emissions

Does your condenser need an evaporative upgrade? Please contact us by filling in the form below or via +31 (0)572 349 400 or info@oxy-com.com.