/Case%20studies%20(Pictures)/Extra/What%20is%20evaporative%20cooling.jpg?width=1080&name=What%20is%20evaporative%20cooling.jpg)

Ventilation, cooling, heating and filtration

IntrCooll: two-stage adiabatic cooling for industrial facilities.

Turn your production hall into a comfortable, healthy and productive workplace.

The benefits of an IntrCooll climate

Comfortable

Perfect temperature and humidity, year-round.

Healthy

Cool with 100% clean, fresh and, filtered outside air.

Sustainable

Environmentally friendly alternative, with 90% lower energy consumption.

Prevent negative pressure

Create comfortable working environment by eliminating uncomfortable drafts.

Industrial climate control

WIHO was looking for a sustainable way to cool their production halls. With the IntrCooll's comfortable cooling, they provide an optimal enviroment on the shop floor. Also, the reliability of the production machines is guaranteed with a maximum temperature tolerance of 2°C. Check out the reference video on WIHO's experience with the IntrCooll. Click here for more two-stage adiabatic cooling references.

Why IntrCooll is different from direct adiabatic cooling

Up to

wet-bulb efficiency

Up to

lower temperatures

Up to

less increase in humidity

Up to

less water consumption

/Book%20cover%20pictures%20(whitepapers%20and%20case%20studies)/EN/Challanges%20and%20opportunities/Challenges%20%26%20Opportunities%20mock%20up%20normal.png?width=800&name=Challenges%20%26%20Opportunities%20mock%20up%20normal.png)

Challenges & Opportunities for Energy-Efficient Climate Control

Discover how to create a sustainable and comfortable climate within your production facility. Download our whitepaper for free:

What IntrCooll can do for your company

Your factory cooled, effortless.

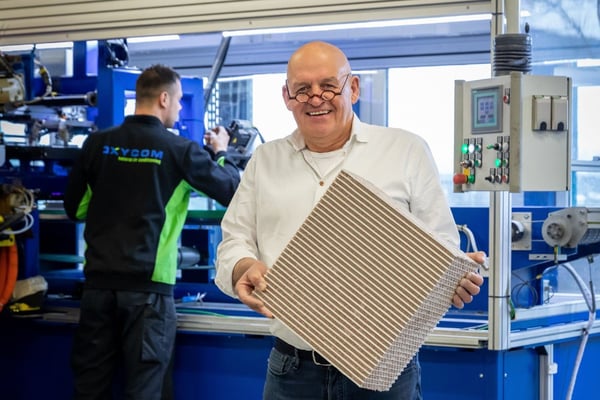

Oxycom's patented two-stage adiabatic cooling

IntrCooll’s products function using the natural principle of water evaporation. Oxycom takes adiabatic cooling to the next level with a unique two-stage indirect / direct adiabatic cooling process. IntrCooll naturally cools water and uses it to cool the air deeper. The result: less moisture and optimal comfort.

90%

energy savings, compared to traditional air conditioning.

/Case%20studies%20(Pictures)/MilliporeSigma/Millipore%20-%20T15.jpeg?width=600&name=Millipore%20-%20T15.jpeg)

Beat the heatwaves with IntrCooll

During the heatwaves of August in the USA, the temperature rose around 44 °C (112 °F). After the installation of our sustainable and innovative two-stage adiabatic cooling solution, IntrCooll, the indoor temperature at MilliporeSigma's pharmaceutical distribution center remained around 23.3 °C (74 °F) due to average supply temperatures around 13 - 14 °C (55.4 - 57.2 °F) and all with 90% energy savings and no harmful cooling agents, but water.

/Case%20studies%20(Pictures)/MilliporeSigma/Brian.jpeg?width=200&name=Brian.jpeg)

Brian Duarte

Regional Manager, MilliporeSigma (USA)

"After the installation of Oxycom’s IntrCooll units, we just smile a lot. Our employees are super happy and our visitors are just totally impressed."

/Case%20studies%20(Pictures)/MilliporeSigma/Brian.jpeg?width=200&name=Brian.jpeg)

Brian Duarte

Regional Manager, MilliporeSigma (USA)

"After the installation of Oxycom’s IntrCooll units, we just smile a lot. Our employees are super happy and our visitors are just totally impressed."

/Case%20studies%20(Pictures)/Aerospace/Aerospace%201.jpg?width=600&name=Aerospace%201.jpg)

The perfect fit for your company

Our broad expertise and knowledge make us the perfect sparring partner. After a thorough analysis of your unique situation, we will consult with the installer and your own experts. We’ll determine how to integrate IntrCooll into your factory. Oxycom's unique modular concepts enable us to quickly create an optimal working climate.

/Case%20studies%20(Pictures)/24%20Tailorsteel/247TailorSteel_NL_Oxycom.jpg?width=600&name=247TailorSteel_NL_Oxycom.jpg)

Get comfortable with our fresh air

IntrCooll cools with 100% fresh and filtered outside air. Constantly ventilating, it refreshes the air several times an hour. This contributes to the comfort and well-being of your employees.

/Case%20studies%20(Pictures)/24%20Tailorsteel/Frank_Gelen-247TailorSteel.jpg?width=200&name=Frank_Gelen-247TailorSteel.jpg)

Frank Gelen

COO, 247TailorSteel

“We wanted to achieve a healthy and comfortable indoor climate in an environmentally friendly and extremely efficient way. With the calculations we received, we were convinced that the Oxycom system would be our best choice.”

/Case%20studies%20(Pictures)/24%20Tailorsteel/Frank_Gelen-247TailorSteel.jpg?width=200&name=Frank_Gelen-247TailorSteel.jpg)

Frank Gelen

COO, 247TailorSteel

“We wanted to achieve a healthy and comfortable indoor climate in an environmentally friendly and extremely efficient way. With the calculations we received, we were convinced that the Oxycom system would be our best choice.”

A comfortable climate, year-round. How it works.

Ventilation

A healthy indoor climate is essential for the well-being of your employees. In summer, IntrCooll uses 100% fresh outside air during free cooling and cooling. By ventilating the contents of the production hall several times an hour, you’re always assured of optimal air quality. The number of air changes in the colder periods depends on the amount of internal heat available. When the system is equipped with the optional Heat Reclaim module, the number of air changes is maximized.

Filtration

You may not always realise it, but outside air is not always clean either. ‘Fresh’ air can be polluted by, for example, pollen, (fine) dust, exhaust gases, bacteria and mold spores. IntrCooll always purifies incoming fresh air before it is blown into the production area. In colder periods we can also guarantee a dust-free indoor climate, by filtering the air recirculated with the Heat Reclaim module. The degree of filtering depends on the chosen filter class.

Heat reclaim

Internal heat generated from machines, processes, heating, lighting and people rises up towards the ceiling by convection. IntrCooll's optional Heat Reclaim module reuses this residual heat. IntrCooll will keep temperatures in your hall consistent, it will supply preheated ventilation air and guarantees a draft-free blow-in. Horizontal temperature layers in your production area are breached (anti-stratification) and the difference in temperature of the roof (between inside and outside) is minimized. This results in less heat loss and therefore provides significant savings.

Heating

If there’s no (air) heating system present and internal heat released from machines is insufficient, the Heat Reclaim module can be equipped with heating batteries. This will heat recirculation air gathered at the ceiling. A pleasant working temperature is established. The module can be combined with all common heating methods such as gas, electric or heat pump. The control of the heating system is prepared as standard, to prevent unnecessary heating.

Free cooling

Even in the spring, winter or fall, cooling of your plant may be required. Despite lower outside temperatures, the indoor temperature can get uncomfortably high. This internal heat is caused by machines, processes and sunlight from windows and skylights. In contrast to traditional cooling systems such as air conditioning, where air is mainly recycled, we use outdoor air smartly with free cooling. This allows us to cool and ventilate your workshop "free of charge".

Indirect/direct adiabatic cooling

When the outside temperature increases further, the system switches to dual-stage adiabatic cooling. The first indirect adiabatic "cooling step" uses cold recirculation water to pre-cool the ambient air. Because no moisture is added, the air has a lower dry bulb and wet bulb temperature than the outside air, when leaving the heat exchanger. The second direct adiabatic "cooling step" cools the air even further through Oxycom's patented Oxyvap. The combined wet bulb efficiency increases to 114%.

/Book%20cover%20pictures%20(whitepapers%20and%20case%20studies)/EN/MilliporeSigma/MilliporeSigma-EN.png?width=800&name=MilliporeSigma-EN.png)

Fresh air and low GHG emissions in the MilliporeSigma distribution center

MilliporeSigma, a leading supplier to the global life science industry, struggled to find an energy-efficient cooling solution in their distribution center at Visalia, California. With our patented two-stage adiabatic climate control, it could achieve a fresh, healthy, and comfortable indoor climate even during the worst heatwave of California.

Discover the unparalleled performance of IntrCooll

Download product brochureIntrCooll Std. |

IntrCooll Plus |

|

|

Nominal air flow |

6000 m³/h at 80 Pa back pressure (3532 ft³/min at 0.32 inAq back pressure) |

14000 m³/h at 80 Pa back pressure |

|

Nominal power |

1290 watt @ 80 Pa back pressure |

3350 watt @ 80 Pa back pressure |

|

Efficiency |

Up to 114% |

Up to 114% |

|

EER (energy efficiency ratio) |

Up to 40 (Up to 136 BTU / (Wh)) |

Up to 40 (Up to 136 BTU / (Wh)) |

|

Dimensions |

1394 mm x 1394 mm x 1074 mm |

2070 mm x 2070 mm x 1460 mm |

|

Weight (dry / in operation) (excluding accessories) |

174 kg / 232 kg |

393 kg / 577 kg |

.png?width=600&name=IntrCooll%20Plus%20+%20NV-Module%20(C).png)

Accessories and options

Do you want to have remote control over your IntrCooll units? The possibility to monitor and control from anywhere in the world on your tablet, smartphone or computer? Oxycom delivers accessories and options to complete your solution.

Your partner in adiabatic cooling

More than 1311 companies preceded you, big and small.

Heat problem in your factory?

Get in touch with Oxycom and see what IntrCooll can do for your business.

Trending Water as a refrigerant

Read the article now

/Case%20studies%20(Pictures)/24%20Tailorsteel/Cooling%20metal%20industry.jpg?width=460&name=Cooling%20metal%20industry.jpg)

/Case%20studies%20(Pictures)/MilliporeSigma/Two%20Stage%20evaporative%20cooling%20USA.jpg?width=460&name=Two%20Stage%20evaporative%20cooling%20USA.jpg)

/Case%20studies%20(Pictures)/Leeb%20Biomilch/Two-stage%20adiabatic%20cooling%20employees.jpg?width=460&name=Two-stage%20adiabatic%20cooling%20employees.jpg)

/Case%20studies%20(Pictures)/Senoplast/Senoplast%20-%20climate%20control%20-%20Oxycom.jpg?width=460&name=Senoplast%20-%20climate%20control%20-%20Oxycom.jpg)